RottguardR-DLP systems make economic sense for the protection of critical assets, such as those seen in Fig. 1 when it is considered that 70% of businesses cease to trade within three years of a serious fire; many of which are caused by electrical faults.

Operation: R-DLP systems extinguish fire automatically in defined spaces, when its pressurized 6 mm tube, attached to the extinguishing agent storage vessel outlet, bursts; on exposure to flame; thus releasing the suppressant; orientated in the direction of the fire.

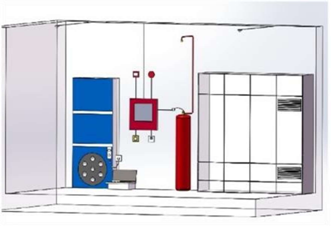

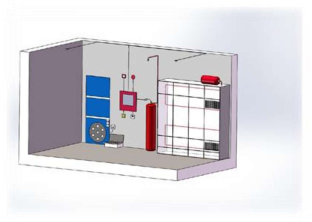

Applications: R-DLP Systems are not intended as replacements for high pressure ones, which protect whole rooms as in Fig. 3; on which door fan air integrity tests are conducted; to ensure their capacity to

retain the extinguishant’s concentration over time.

R-DLP pre-engineered fixed fire suppression systems are an ideal standalone solution for the protection of the electrical cabinets as seen in Fig. 4. They can also be used to supplement those designed to protect whole rooms, as seen in Fig. 5.

This practice of having two fire suppression systems in the same area, is not uncommon; in instances where insurers perceive the risk to be high, in areas of reoccurring fires.

Fig. 6 shows a R-DLP system, as installed for the protection of electrical cabinets in a Saudi Arabian electrical substation; where the customer specified the use of white extinguishant storage cylinders.

The R-DLP system in that instance was an ideal cost-effective means of protecting the electrical switch gear alone, in what was otherwise a large empty substation.

As all modern electrical enclosures have IP rated door seals, it is not inconceivable that a gaseous extinguishant, might not permeate into their individual cubicles as quickly; from a system designed to protect the whole room; as that emitted within; from a R-DLP system.